€521.33*

Available, delivery time: 1–3 weeks (delivery in even calendar week in BE, FR, LU, NL)

Queenply. The original

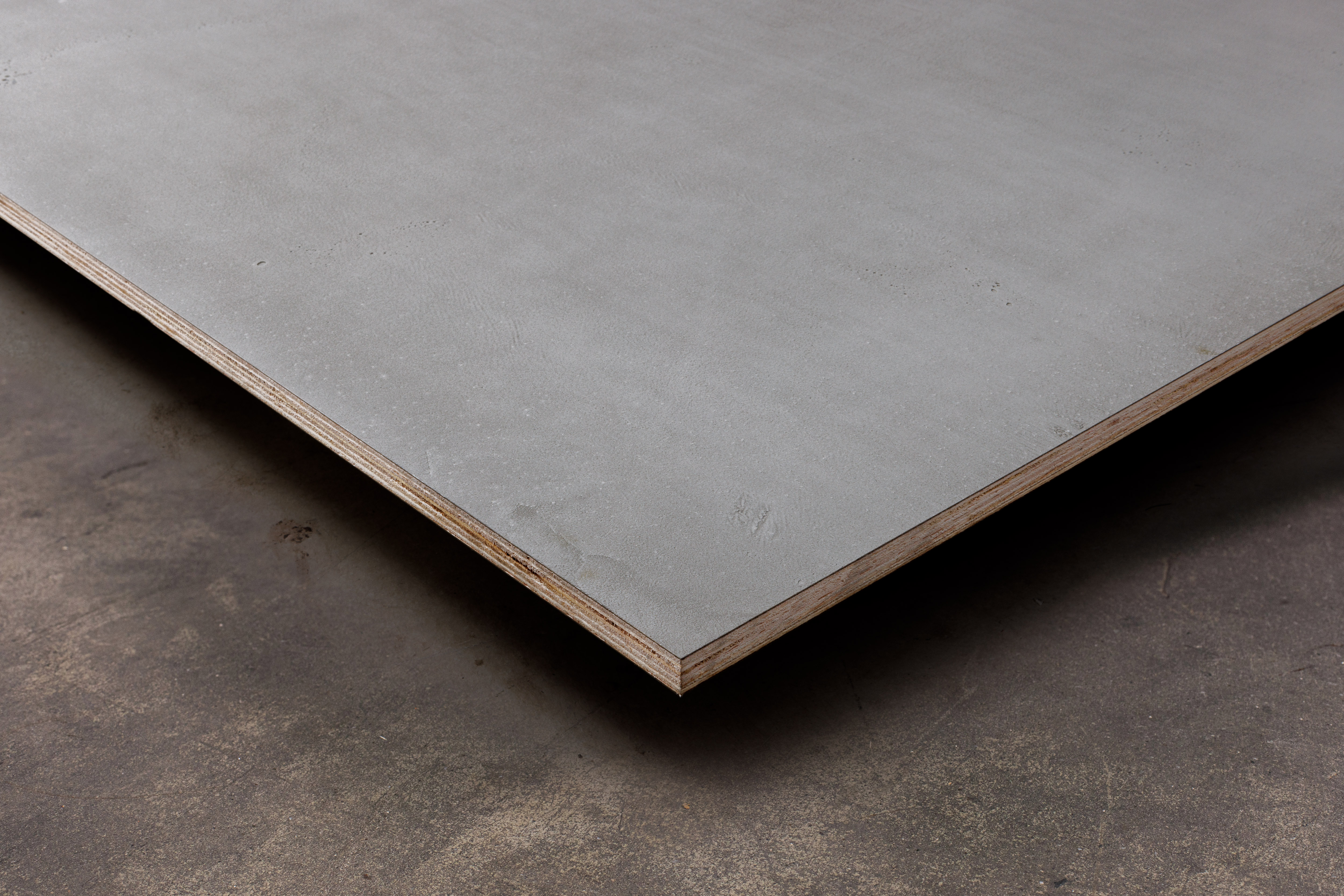

- extremely light — extremely stable

- carrier board with 11 layers (thickness 15 mm)

- calibrated to an accuracy of 0.2 mm

- made from sustainably grown wood

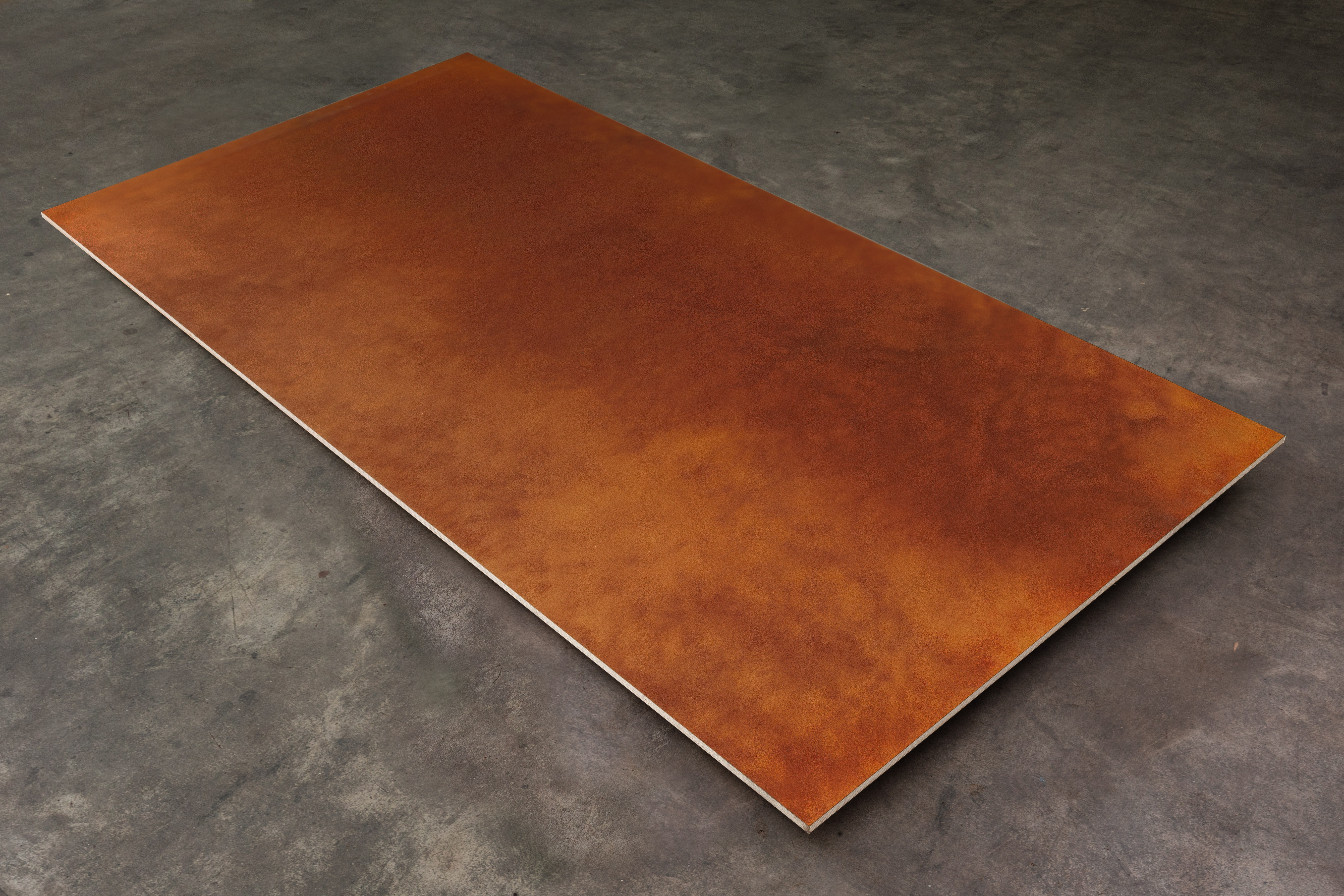

Rust style on multiplex. Best lightweight panel in old rust style. For many creative ideas.

Now that's something completely different! A multiplex panel with a rust surface. Are you already thinking about what you can build with it? Go ahead, we are very excited!

Our rust surface can be used in many ways. You can use it in furniture construction, as wall cladding, on ceilings or stairs, in trade fair or shop construction – there are almost no limits to your ideas. Especially in contrast with other HPL or acrylic surfaces, you can create truly extraordinary combinations.

The coating is smooth and consists of mineral, solid-coloured materials – and real metal particles. At the same time – and this is also very important to us – it is ecologically harmless and recyclable.

And for the most comfortable and simple processing possible, we naturally apply the decor to our best lightweight panel: Queenply. The low weight (approx. 320 – 350 kg/m3) makes processing easier for you. You don't have to carry and install the mass of real iron panels! For more technical information, just take a look at the "Technical details".

| Carrier plate: | Queenply with 11 layers (15 mm thickness) |

|---|---|

| Format: | 241 × 118,5 cm |

| Thickness: | 17,2 mm |

| Weight: | 23,68 kg |

| Coating: | Rust |

The Queenply Multiplex imi-rust is available in 17.2 mm or 20.2 mm thickness in our shop. We coat one side of the Queenply in rust look, the back side is covered with a very noble looking, matching HPL in black. The carrier panel is either 15 mm or 18 mm thick. You have the choice. The rust characteristic has no unwinding. Each Queenply coating is unique. However, a uniform appearance is always guaranteed.

The grate surface consists of mineral, solid-coloured material with a proportion of real metallic iron particles. This means that the plates are slightly magnetic.

The carrier panel is of course our extremely light Queenply Multiplex panel and it is so much lighter than birch multiplex or poplar plywood. You use iron plates, but you save weight, you can work the plates very easily and at the same time you have a really cool look. We can't wait to see what you make of it!

We calibrate the carrier panel accurate to 0.2 mm to obtain a lower thickness tolerance.

By using the PUR hot melt process, we give the lightweight panel a moisture-resistant gluing of the middle layers. And it is precisely this multiplex structure that gives you a finishing panel with high screw pull-out resistance and particularly good stability.

We will also have suitable edgings and accessories for corner construction in our shop next week. You’ll find them in the accessories section.

Multiplex beams such as the Queenply Multiplex imi-rost do not have the same surface properties as chipboard or MDF beams. Any surface irregularities that may occur are in the nature of the carrier and are no reason for a complaint. Production or material-related minimal defects that do not affect the product quality and are permissible within the 1st choice are assessed according to the grading regulations based on DIN EN 438 and the international ISO standardisation.

We also take great care to ensure that your ordered Queenply panels leave our factory in perfect condition and arrive undamaged. You can rely on that! However, we would also like to point out that any distortion of the panels caused by transport or further storage is not grounds for complaint.

Please also note that the representation of the coloring on your screen may differ slightly from the original color! If you have any questions, please contact us. To be on the safe side, you can order a sample of all Queenply variants from our shop.

If you are going to process our lightweight panel, please ensure that you take adequate safety precautions, such as extracting the chips and wearing safety goggles and a protective mask. Due to the low weight, there is an increased dust formation when processing the Queenply.

And another important note:

We pack your finishing panels with particular care before dispatch and ensure that they leave our warehouse without damage to the edges. However, even with the greatest care, it can happen during transport that a corner is dented or the edge is slightly damaged. We know that too. That's why we calculate 1 cm less for each side of every Queenply finishing panel in advance: 249 cm × 121 cm for the raw board, 243 cm × 121 cm for all composite elements and 247 cm × 120 cm for all veneered panels. This saves us all a lot of time that would otherwise be wasted on complaints. Put this time into your project – and feel free to recommend us to others.