Exclusively only from us!

ORIGINAL QUEENPLY. The lightest finishing panel for your project!

In our online shop, we have the extremely lightweight Queenply finishing panels and furniture construction boards in our programme for you. You can get the high-quality original only from us.

In different thicknesses. Covered with HPL or acrylic. Or with real wood veneers. And with unusual decors such as rust or concrete. You have the construction idea. We have the perfect worktop, we bet.

Just take a look around:

QUEENPLY

Compound Elements QUEENPLY

Veneered panels QUEENPLY

untreated QUEENPLY

floor finishing panel

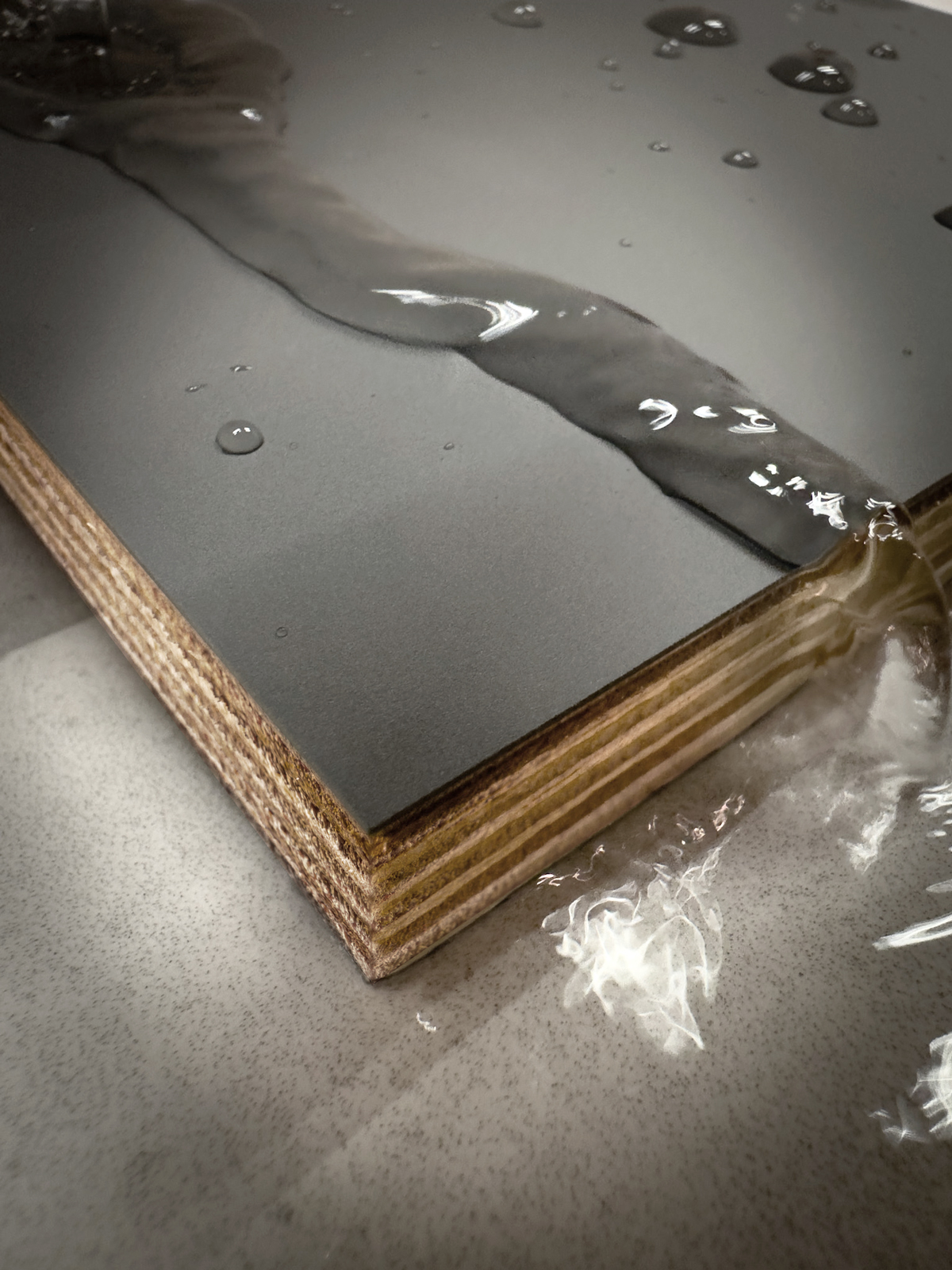

Smooth surface

The PUR foam applied to the Queenply has a great side effect: it also evens out small irregularities in the surface.

As a result, we achieve a much smoother surface than with conventional glues. This is particularly noticeable with dark unit colours, extremely matt surfaces and high gloss.

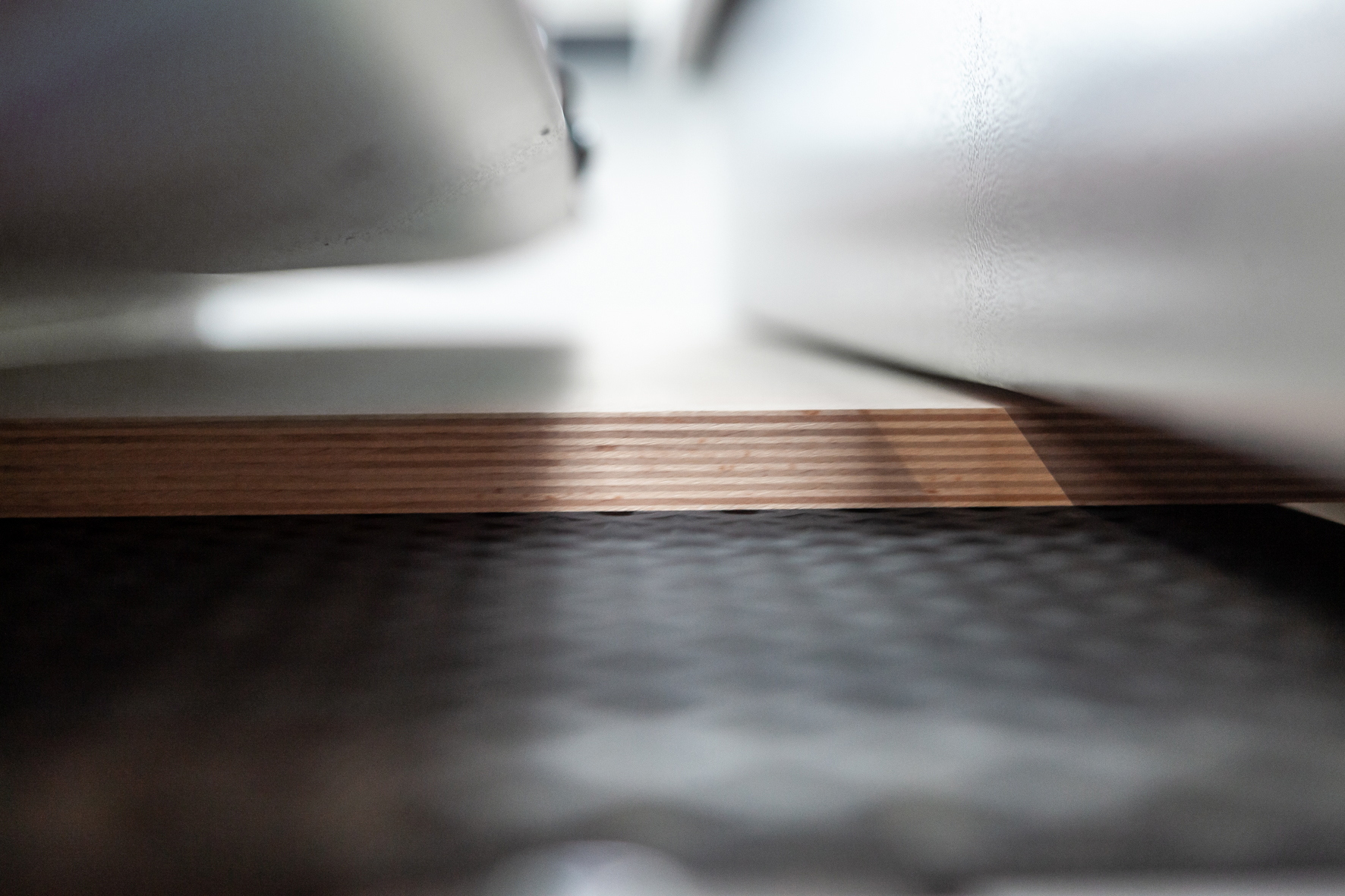

Calibration

Through additional calibration, we achieve a thickness tolerance of 0.2 mm for all Queenply sheets.

This gives you several advantages during further processing: No hassle with higher thickness tolerances, as everything fits with millimetre precision. This guarantees perfect gap dimensions when building furniture. And our calibration saves you trouble, labour and money during the finishing process.

Higher number of centre layers

In our Queenply core panels, we always incorporate more centre layers than usually necessary. This applies to all Queenply variants. This means in detail:

| Strength | Amount |

|---|---|

| 4 mm | 5 layers |

| 6 mm | 5 layers |

| 9 mm | 7 layers |

| 12 mm | 9 layers |

| 15 mm | 11 layers |

| 18 mm | 13 layers |

| 22 mm | 15 layers |

This production method guarantees you a significantly higher stability and at the same time a particularly high screw pull-out strength. Fittings and screws do not tear out as quickly as with other finishing panels. Not even when you are travelling off-road with your van or expedition vehicle. Everything you build with our panels lasts.

Even with a higher number of centre layers than usual, we manage to make our panels significantly lighter than birch or poplar thanks to our high-quality raw material and high-quality processing.

Stability

The higher number of centre layers gives the Queenply lightweight panels extremely high stability and a high screw pull-out strength. This makes it really fun to build sustainable and durable furniture and plan extensions.

For all van fans among us: Queenply is therefore also suitable for off-road vehicles.

For all property furnishers: If Queenply can withstand off-road driving, it is certainly also a really good extension board for living areas, isn't it?

Decor Selection

The vast majority of our professional customers and do-it-yourself customers are not only impressed by the technical properties, but also by the wide selection of high-quality decors that we can offer you.

Despite all the technical finesse, the look also has to be right, of course: a variety of decors, brilliant colors, velvety surfaces, elegant wood tones with beautiful grains, unusual rust or concrete surfaces.

We could go on like this forever. Just take a look for yourself in our shop.

Available at short notice

Sure: If you want to start your project, the lightweight panels should also be available promptly.

That's why we have a large warehouse and lots of Queenply lightweight panels in stock. Our shuttle will bring your order directly to your door for 49 euros. Transport is carried out by our trained drivers, who know exactly how to handle our wood-based materials.